NON-WOVEN GEOTEXTILE

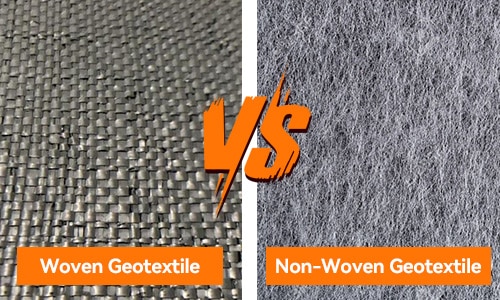

Non-woven geotextiles are used in construction and civil engineering projects primarily for filtration, drainage, and protection. Unlike woven geotextiles, which are made by weaving fibers together, non-woven geotextiles are manufactured by bonding fibers together through heat, needle-punching, or chemical processes. Here’s why non-woven geotextiles are widely used:

Non-woven geotextiles are synthetic fabrics made by bonding long fibers together through mechanical, thermal, or chemical processes, rather than weaving them. These geotextiles are primarily used in civil engineering and construction projects for filtration, drainage, separation, and protection purposes. Their felt-like texture and high permeability make them especially effective in managing water flow while preventing soil migration, which is crucial in applications like road subgrade stabilization, drainage systems, retaining walls, and erosion control. Non-woven geotextiles also serve as a protective layer over geomembranes in landfill liners and pond installations, guarding against punctures and damage from sharp objects. Their flexibility allows for easy installation over irregular surfaces, and they adapt well to uneven terrain. Overall, non-woven geotextiles provide a cost-effective and durable solution for enhancing the performance and longevity of infrastructure where water flow and soil stability are key considerations.

Non-woven geotextiles are synthetic fabrics made by bonding long fibers together through mechanical, thermal, or chemical processes, rather than weaving them. These geotextiles are primarily used in civil engineering and construction projects for filtration, drainage, separation, and protection purposes. Their felt-like texture and high permeability make them especially effective in managing water flow while preventing soil migration, which is crucial in applications like road subgrade stabilization, drainage systems, retaining walls, and erosion control. Non-woven geotextiles also serve as a protective layer over geomembranes in landfill liners and pond installations, guarding against punctures and damage from sharp objects. Their flexibility allows for easy installation over irregular surfaces, and they adapt well to uneven terrain. Overall, non-woven geotextiles provide a cost-effective and durable solution for enhancing the performance and longevity of infrastructure where water flow and soil stability are key considerations.

✅ 1. Excellent Filtration:Non-woven geotextiles allow water to pass through while filtering out soil particles. This prevents clogging and maintains the performance of drainage systems, making them ideal for use in French drains, retaining walls, and under roads.

✅ 2. Effective Drainage:Their high permeability helps manage subsurface water by allowing water to flow freely, which reduces water pressure buildup and prevents erosion or structural damage in soil structures.

✅ 3. Soil Separation:Non-woven geotextiles effectively separate different soil layers, preventing the mixing of aggregate and subgrade. This improves soil stability and extends the life of roads, railways, and pavements.

✅ 4. Protection Layer:They are commonly used as cushioning layers to protect geomembranes from puncture in landfill liners, reservoirs, and ponds, ensuring long-term durability of containment systems.

✅ 5. Flexible and Easy to Install:Their soft, fabric-like texture allows for quick and easy installation over uneven surfaces, around curves, or in tight spaces, reducing labor and time costs on-site.

✅ 6. Cost-Effective:Non-woven geotextiles are generally more affordable than woven types when the primary needs are filtration and protection, offering a budget-friendly solution without compromising performance

.

non-woven geotextiles are versatile, water-permeable, and protective, making them perfect for a wide range of drainage, filtration, and stabilization applications in civil and environmental engineering.