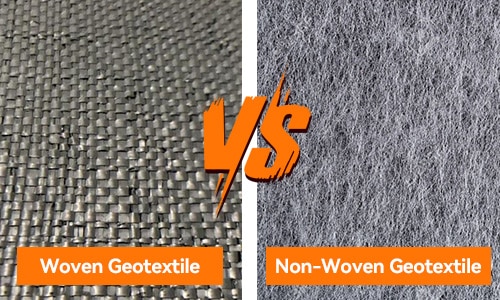

WOVEN GEOTEXTILE

Road woven geotextiles are engineered fabrics made from synthetic fibers like polypropylene or polyester that are woven together to form a robust, high-strength material. These geotextiles are primarily used in road construction to provide critical functions such as separation, reinforcement, filtration, and drainage. When placed between the subgrade soil and the aggregate base layers, woven geotextiles prevent the mixing of different soil layers, which helps maintain the structural integrity of the road. Their woven structure allows for high tensile strength, which is essential for distributing loads and reducing deformation under heavy traffic. They also help manage water flow by allowing water to pass through while preventing soil particles from migrating, thereby enhancing the drainage and stability of the roadway.

1.High Tensile Strength: Woven geotextiles are made by interlacing strong synthetic fibers, typically polypropylene or polyester. This gives them excellent load-bearing capabilities, which helps distribute weight and pressure over a larger area, reducing stress on the subgrade.

1.High Tensile Strength: Woven geotextiles are made by interlacing strong synthetic fibers, typically polypropylene or polyester. This gives them excellent load-bearing capabilities, which helps distribute weight and pressure over a larger area, reducing stress on the subgrade.

2.Soil Separation: One of their main purposes is to separate different layers of materials—like preventing the mixing of soil and aggregates. This maintains the road's structural integrity over time.

3.Reinforcement: By adding strength to weak soil layers, woven geotextiles improve the ground’s load-bearing capacity. This reinforcement reduces rutting and deformation, especially under heavy or repetitive loads.

4.Cost-Effectiveness: Because they improve soil performance, they can reduce the thickness of aggregate layers required for construction. This leads to savings in material and labor costs.

5.Durability: Woven geotextiles are resistant to degradation from chemicals, UV exposure, and biological agents, making them suitable for long-term use in harsh environments.

6.Improved Drainage: While not as permeable as non-woven geotextiles, some woven types allow limited water flow, which helps manage subsurface water without losing soil particles—preventing erosion.

The advantages of using woven geotextiles in road construction are numerous. One of the key benefits is their ability to extend the lifespan of roads by minimizing rutting, cracking, and subsidence caused by unstable soil conditions. This ultimately reduces maintenance costs and improves road safety. Additionally, by improving load distribution, woven geotextiles allow for thinner aggregate layers, which can significantly lower construction costs. Their resistance to biological and chemical degradation also makes them suitable for various environmental conditions, ensuring long-term performance. Overall, woven geotextiles provide a cost-effective, durable, and sustainable solution for enhancing the strength and durability of roads, especially in areas with weak or variable subsoil conditions.

woven geotextiles are chosen for their ability to reinforce, separate, and stabilize soils, making them essential in building strong, long-lasting roads, embankments, retaining structures, and more.